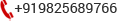

Product Description

Offered in different specifications, these Scroll Spreader Rolls are used in drying section of paper industry. These rolls are made of seamless stainless steel pipes and are provided with chrome plated surface. Quality of thee spreader rolls is determined on the basis of roughness level, dynamic balance test, thickness of their surface cover layer, outer diameter range and installation technique of their bearing. Chamfering and hardness tests are also conducted to measure their flawlessness. Long lasting surface finish, high durability, ease of installation, trouble free removal method and low maintenance design are their key factors. We are a reliable supplier and manufacturer of Scroll Spreader Rolls.

Features:

- Stainless steel body

- Chrome plated surface

- Exceptional durability

- Precise design

Precision Engineering and VersatilityScroll Spreader Rolls are crafted using advanced CNC machining techniques, guaranteeing high accuracy and excellent surface finish. With the ability to customize dimensions, length (500 mm 6000 mm), and diameter (85 mm 300 mm), these rolls adapt seamlessly to diverse industry requirements. Each unit supports belts 300 mm to 4500 mm wide, catering to demanding production environments.

Robust Construction and Reliable OperationConstructed from stainless steel, aluminum, or rubber-coated materials, these spreader rolls boast non-corrosive surfaces suitable for prolonged industrial use. Dynamic balancing and robust mounting types ensure stable, vibration-free performance even at capacities up to 2000 kg/hr, enabling optimal productivity in textile, paper, and related sectors.

FAQs of Scroll Spreader Rolls:

Q: How are Scroll Spreader Rolls installed across different machinery?

A: Scroll Spreader Rolls can be mounted using either flange or foot mounting options, making them compatible with a wide variety of machine configurations. Installation is user-friendly and typically requires basic tools, ensuring minimal downtime during replacement or setup.

Q: What benefits do the non-corrosive materials provide in industrial applications?

A: Non-corrosive materials like stainless steel and high-quality rubber coatings prevent oxidation and degradation, ensuring long-lasting performance in harsh environments. This enhances durability and reduces the frequency of maintenance or replacement.

Q: When should I consider using a custom dimension for Scroll Spreader Rolls?

A: Custom dimensions are ideal when your machinery specifications fall outside standard size ranges. You can request tailored lengths and diameters to fit unique requirements, ensuring precise integration and optimal functionality for your operation.

Q: Where are these spreader rolls commonly used?

A: Scroll Spreader Rolls are extensively used in textile, paper, plastic, and printing industries. They are particularly suitable for processes that require uniform spreading and wrinkle control across extensive belt widths.

Q: What is the process for ensuring dynamic balancing on these rolls?

A: Each roll undergoes a dynamic balancing process during manufacturing. This involves precise adjustments to eliminate vibrations when the roll is in motion, resulting in smoother operation and reduced wear on machinery components.

Q: How does the ISO 9001:2015 certification benefit customers?

A: ISO 9001:2015 certification assures customers of consistent product quality and standardized manufacturing processes. This global benchmark enhances trust, reliability, and compliance with international industrial standards.